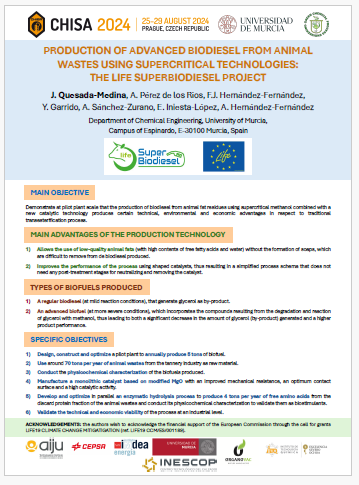

The Life Superbiodiesel Project, represented by the Chemical Engineering Department of the University of Murcia, contributed to the 27th International Congress of Chemistry and Process Engineering with the presentation of the poster “Production of advanced biodiesel from animal wastes using supercritical technologies”. This participation allowed sharing with the international scientific community the project’s advances in developing supercritical technologies for the production of advanced biodiesel from animal waste.

The poster presented the main objectives and achievements of the Life Superbiodiesel project, whose fundamental goal is to demonstrate, at pilot plant scale, the technical, environmental, and economic advantages of biodiesel production from animal fat waste using supercritical methanol combined with an innovative catalytic technology. The developed technology stands out for allowing the use of low-quality animal fats with high content of free fatty acids and water, avoiding soap formation, as well as for the use of shaped catalysts that simplify the process by eliminating post-treatment stages. The project contemplates two types of biofuels: a conventional biodiesel produced under mild reaction conditions, and an advanced biofuel obtained under more severe conditions, which incorporates compounds resulting from glycerol degradation and reaction with methanol, significantly reducing byproduct generation and improving yield. Among its specific objectives are the design and optimization of a pilot plant capable of producing 5 tons of biofuel annually, the potential valorization of 70 tons per year of animal waste from the tanning industry, the development of a monolithic catalyst based on modified MgO, and the parallel production of 4 tons per year of free amino acids as biostimulants through enzymatic hydrolysis, all aimed at validating the technical and economic viability of the process at industrial scale.

It is estimated that around 240 people had access to the poster, of which approximately 17 expressed specific interest in the project and its results.

Comments are closed.